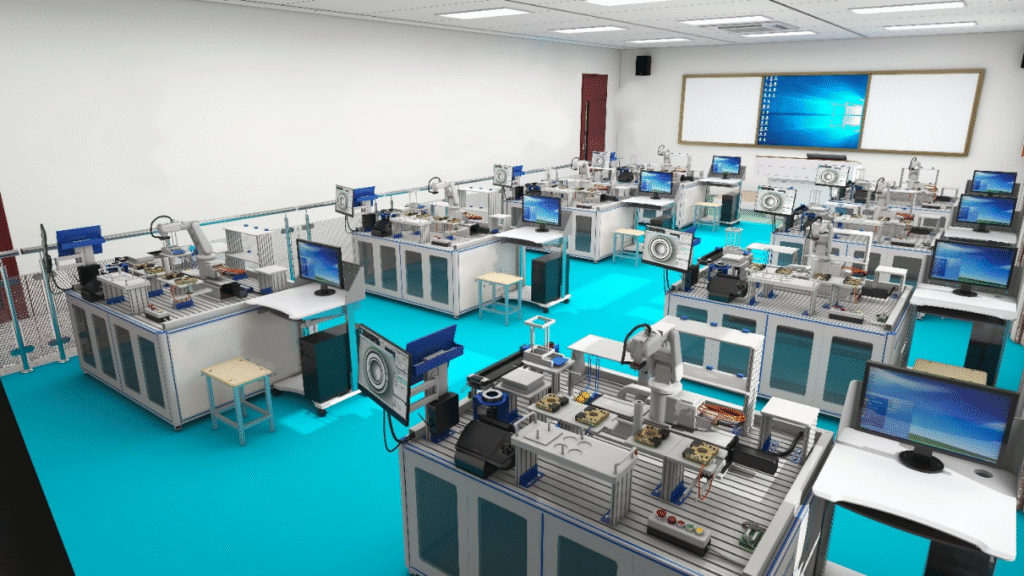

The six-axis industrial robot training equipment consists of the industrial robot body, robot base, robot control cabinet and teach pendant, and industrial robot offline operation platform.

- Robot Technical Parameters:

Number of Axes: 6;

Robot Type: Small General-Purpose Industrial Six-Axis Robot;

Weight: ≥25kg;

Maximum Payload: ≥3kg;

Working Range:

Maximum Horizontal Working Range: ≥560mm; Maximum Horizontal Working Angle Range: ≥330°;

Pickup Height Below Base: ≥112mm;

Motion Performance:

Axis 1 (Closest to Base): Range ≥+165°~-165°, Maximum Speed ≥250°/s;

Axis 2: Range ≥+110°~-110°, Maximum Speed ≥250°/s;

Axis 3: Range ≥+70°~-90°, Maximum Speed>230°/s;

Axis 4: Range ≥+160°~-160°, Maximum Speed ≥320°/s;

Axis 5: Range ≥+120°~-120°, Maximum Speed ≥320°/s; 1. Axis 6 (End-effector): Range ≥ +400°~ -400°, Maximum speed ≥ 420°/s; Maximum speed at the center point of the industrial robot’s end effector: 6.2m/s; Maximum acceleration at the center point of the industrial robot’s end effector: 28m/s²; Time to accelerate from rest to 1m/s: 0.07s; Repeat positioning error: ≤0.01mm; - Standard Aluminum Profile Training Platform

Overall height: 880mm, ergonomically designed for easy operation. - Quick-change tool kit

- Industrial parts training kit

- Drawing training module

- Intelligent palletizing module

- Industrial electrical interface kit

- Automated warehousing module

- Pit-type feeding module

- Belt conveyor module

- Precision assembly module

- Industrial controller kit

- RFID identification module

- Vision inspection module

- Oil-free silent air compressor